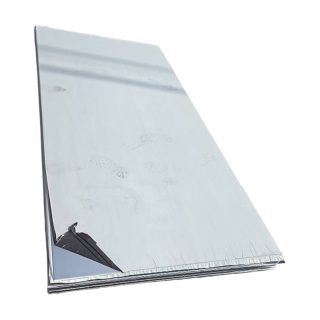

201, 202 Stainless Steel Plate

201 stainless steel sheet is a cost-efficient stainless steel material, balancing performance, workability and price.

201, 202 Stainless Steel Plate

The 200 series of low nickel austenitic stainless steels.

Traditionally only popular in the United States, the 200 series of stainless steels are becoming more popular worldwide due to the significantly lower nickel content than the 300 series. As the price of nickel has risen, this has driven more interest in the 200 series as a viable and cost-effective alternative.

With this increased interest, producers of stainless steels have been refining the 200 series with enhanced grades and new grades. Although typically to fulfil a specific requirement for a particular application, these new grades are often simply improvements to existing grades.

|

Thickness |

0.3-200mm |

|

Length: |

2000mm, 2438mm, 3000mm, 5800mm, 6000mm,12000mm,etc |

|

Width |

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

|

Standard: |

ASTM,JIS,GB,DIN,EN |

|

Surface: |

BA,2B,NO.1,NO.4,4K,HL,8K |

|

Application: |

It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components. It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

|

Certification: |

ISO, SGS,BV |

|

Technique: |

Cold Rolled Hot Rolled |

|

Edge: |

Mill Edge Slit Edge |

|

Grade (ASTM,JIS,GB,DIN) |

201 202,SUS201SUS202,12Cr17Mn6Ni5N12Cr17Mn6Ni5N,1.43721.4373, |

Chemical Composition and Mechanical Property

|

Grade |

C(%) |

Si(%) |

Mn(%) |

P(%) |

S(%) |

Cr(%) |

Ni(%) |

N(%) |

Cu(%) |

|

201 |

≤0.15 |

≤0.10 |

5.50-7.50 |

≤0.06 |

≤0.03 |

16.0-18.0 |

≤1.0 |

≤0.25 |

0.80-1.50 |

|

202 |

≤0.15 |

≤0.10 |

5.50-7.50 |

≤0.06 |

≤0.03 |

14.0-15.0 |

4.0-6.0 |

≤0.25 |

0.80-1.50 |

|

Grade |

Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

Rate Of Reduction In Area (%) |

Density (G/Cm3) |

Hardness (HRB) (HBS) (HV) |

|

201 |

≥520 |

≥275 |

50-60 |

—– |

7.93 |

HRB≤100 |

|

202 |

≥520 |

≥275 |

50-60 |

—– |

7.93 |

HBS≤207 HRB≤95 HV≤218 |

More details for 201,202

|

Grade |

Production Type (CR/HR) |

Thickness (MM) |

Width (MM) |

Finish |

Origin |

|

201/202 |

Cold Rolled Technical Sheet/Coil/Strip |

0.30-3.00 |

1000 1219 1500 Or Customized |

2B BA No.4(Brushed) HL(Hairline) 8K(Mirror) Golden |

LISCO |

|

Hot Rolled Technical Plate/Coil/Strip |

3.00-10.00 |

1219 1240/1250 1500 Or Customized |

No.1 No.4(Brushed) HL(Hairline) 8K(Mirror) |

TianCheng |

| Applications | Furniture |

| 200 series austenitics are typically used to replace types 304 and 301 as well as carbon (chrome-manganese) steels mainly for indoor use for low corrosion applications at room temperature. |

Bins Safety Shoes (mid-sole protector) Industrial Strapping Railway Rolling Stock There is also grade 201LN for welded constructions, structural uses and low temperature applications. Examples include: Sides & roofs of trains Liquified gas storage vessels Structural members/chassis of railway rolling stock, trucks & trailers Coal handling equipment |

|

· Cooking utensils · Restaurant equipment · Appliances · Automotive trim · Architectural applications · Windows & channel spacers · Doors · Railway cars · Trailers · Hose clamps |

Characteristics

· Lower nickel than 300 series – with it being replaced by manganese

· Lower cost than 300 series

· Similar mechanical & physical properties to 300 series

· Similar fabrication performance to 300 series, including deep-drawing

· Corrosion resistance similar to 430 (i.e. not nearly as good as 300 series)

· High carbon may cause stress corrosion cracking, especially after welding thicker material

· Non Magnetic

· Performance Comparison:

· Formability: Similar to 304, better than 430

· Strength: Stronger than 304 (and 430)

· Corrosion Resistance @20 C: Similar to 304, better than 430 but susceptible to stress corrosion cracking/intergranular corrosion especially after welding

Related products

-

Contact Us

Stainless steel round bars are typically available in various grades, sizes, and finishes to cater to different industrial requirements. Stainless steel round bars find applications across various industries, including:

Construction: In the construction industry, stainless steel round bars are used in bridges, skyscrapers, and other structural applications due to their corrosion resistance and high strength. -

Contact Us

● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month;

● Payment terms L/C, T/T;

● It can pack by container or bulk vessel.

● Standard export seaworthy package, it use steel belt with bundle according product’s size.

● We can make it as your requirement.

Reviews

There are no reviews yet.