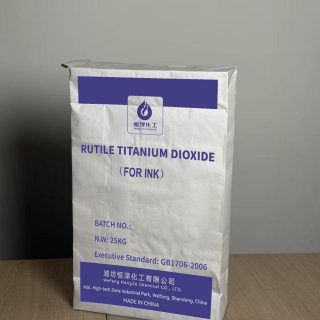

HZR818 Rutile TiO2 for Plastics & Masterbatch

This rutile titanium dioxide, produced via the sulfate process, is engineered to meet the demanding requirements of the plastics and masterbatch industries.

HZR818 Rutile TiO2 for Plastics & Masterbatch

Key Features:

-

Excellent Whiteness & Blue Undertone: Provides a bright, clean base for producing vibrant and appealing plastic products.

-

Superior Dispersibility: Specifically treated to ensure easy integration and uniform distribution within polymer matrices, reducing processing time and energy consumption.

-

Good Thermal Stability: Withstands high processing temperatures, minimizing degradation and yellowing in applications like injection molding.

-

High Weathering Resistance: Suitable for plastic products requiring good durability against environmental factors.

-

Low Moisture Absorption: Ensures smooth processing and prevents issues like porosity in the final product.

Applications:

Ideal for PVC profiles and pipes, polyolefins (PP, PE), masterbatch, engineering plastics, and synthetic fibers.

Specifications:

Type: Rutile

Grade: For Plastics & Masterbatch

Process: Sulfate

Executive Standard: GB/T 1706-2020

Net Weight (N.W.): 25 kg/bag

Batch No.: (Refer to product packaging)

TDS (Technical Data Sheet):

|

Property |

Value |

|

TiO₂ Content |

≥ 94.5 % |

|

Brightness |

≥ 95.0 % |

|

Volatile at 105°C |

≤ 0.5 % |

|

pH Value |

6.5 – 8.0 |

|

Oil Absorption |

≤ 18 g/100g |

|

Residue on 45μm Sieve |

≤ 0.03 % |

|

Tint Reducing Power |

≥ 1980 |

|

Rutile Content |

≥ 99.3 % |

|

Specific Resistance |

≥ 80.0 Ωm |

|

Color Index |

Pigment White 6 |

|

Dispersibility |

≥ 6.50 |

|

ISO 591-1:2000(E) |

R2 |

|

ASTM D476-00 |

V |

Reviews

There are no reviews yet.