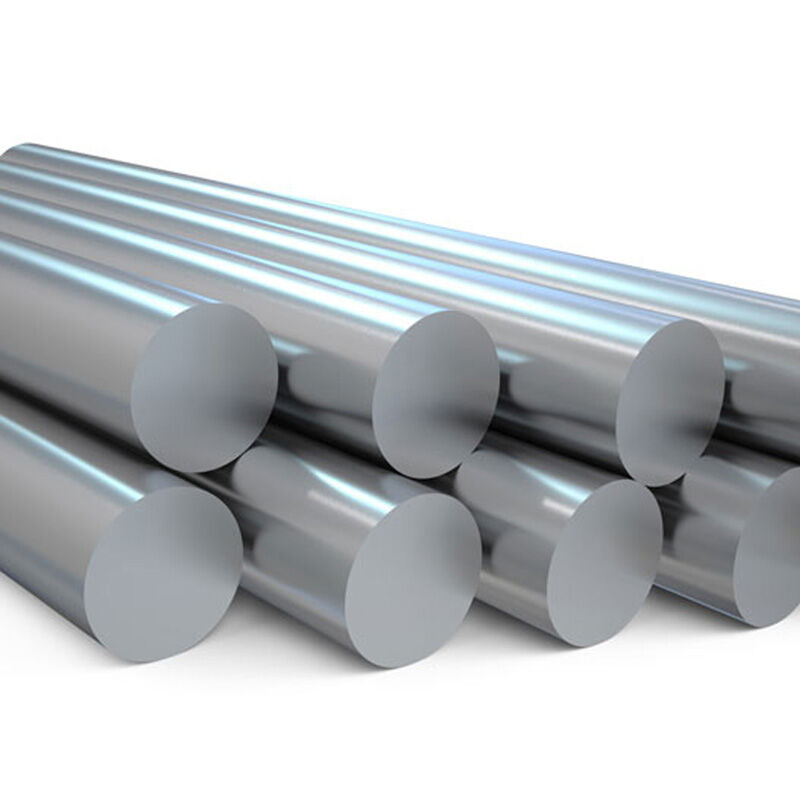

904L Stainless Steel Bar

Stainless steel round bars are typically available in various grades, sizes, and finishes to cater to different industrial requirements. Stainless steel round bars find applications across various industries, including:

Construction: In the construction industry, stainless steel round bars are used in bridges, skyscrapers, and other structural applications due to their corrosion resistance and high strength.

| Product Name | stainless steel round bar |

| Material | stainless steel |

| Grade | 310S,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L,301,302,201, 202,405,409,410,420,430,S32304,S31803,S32550,S32750,S31500,S31260,SS2377 ,SS2327,SS2376,etc |

| Standard | ASTM, AISI, JIS, DIN, GB, EN |

| Outer Diameter | 4~800mm |

| Length | 5.8m,6m,or as required |

| Shape | Round |

| Surface | Black,peeled,polishing,bright,sand blast,hair line,etc |

| Applications | Stainless steel bar applies to petroleum, chemical industry, electric power, boiler, high temperature resistant, low temperature resistant, corrosion resistant Stainless steel bar can be made according to the customers requirements. |

| Samples | Kindly Discuss with Sales Staff |

| Lead Time | Depends on Specifications, Quantity etc. |

| Package | Standard Seaworthy Package or as required |

|

|

|

|

|

Finish |

Definition |

Application |

|

|

JIS G4305 |

No. 2 D |

Those finished , after cold rolling , by heat treatment , pickling or other equivalent treatment . In addition , those rolled lightly by matting roll at the last stage are also included . |

Medical equipment, Food industry, Construction material, Kitchen utensils. |

|

No. 2 B |

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. |

||

|

No. 3 |

Those finished by polishing with No. 100 to No. 120 abrasives specified in JIS R 6001. |

Kitchen utensils, Building construction. |

|

|

No. 4 |

Those finished by polishing with No. 150 to No. 180 abrasives specified in JIS R 6001. |

Kitchen utensils, Building construction, Medical equipment. |

|

|

#240 |

Those finished by polishing with No. 240 abrasives Specified in JIS R 6001 . |

Kitchen utensils, Electric equipment, Building construction. |

|

|

#320 |

Those finished by polishing with No. 320 abrasives Specified in JIS R 6001 . |

||

|

#400 |

Those finished by polishing with No. 400 abrasives Specified in JIS R 6001 . |

||

|

BA |

Those processed with bright heat treatment after cold rolling. |

||

|

HL |

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. |

Building Construction. |

|

|

ASTM A480 |

No. 2D |

Cold-rolled , dull finish ; |

A smooth , nonreflective cold-rolled annealed and pickled or descaled finish . This nondiredtional finish is favorable for retention of lubricants in deep drawing applications . |

|

No. 2B |

Cold-rolled , bright finish ; |

A smooth , moderately reflective cold-rolled annealed and pickled or descaled finish typically produced by imparting a final light cold-rolled pass using polished rolls . This general-purpose finish is more readily polished than No.1 or 2D finishes . |

|

|

Bright Annealed |

A bright cold-rolled finish retained by final annealing in a controlled atmosphere furnace . |

A smooth , bright , reflective finish typically produced by cold rolling followed by annealing in a protective astmosphere so as to prevent osidation and scaling during annealing . |

|

|

No. 3 |

Intermediate polished finish , one or both sides . |

A linearly textured finish that may be produced by either mechanical polishing or rolling . Average surface roughness ( Ra) may generally be up to 40 micro-inches . …… |

|

|

No. 4 |

General purpose polished finish , one or both sides . |

A linearly textured finish that may be produced by either mechanical polishing or rolling . Average surface roughness ( Ra) may generally be up to 25 micro-inches . …… |

|

|

No.6 |

Dull stain finish , Tampico Brushed , one or both sides . |

This finish has a soft , satin appearance typically produced by tampico brushing a No.4 finish . |

|

|

No. 7 |

High luster finish . |

Has a high degree of reflectivity . |

|

|

No. 8 |

Mirror finish . |

This is a highly reflective , smooth finish typically produced by polishing with successively finer grit abrasives . Then buffing . |

|

|

TR |

Cold-worked to obtain specified properties . |

The finish resulting from the cold-rolling of an annealed and descaled or bright annealed product to obtain mechanical properties higher tahn that of the annealed condition . |

|

|

GB/T 3280-2015 |

2E |

Cold rolled , heat treated , mechanically descaled . |

Rough and dull . |

|

2D |

Cold rolled , heat treated , pickled or descaled . |

The surface is uniform and matte . |

|

|

2B |

Cold rolled , heat treated , pickled or descaled , skin passed . |

Smoother and straighter than 2D surface . |

|

|

BA |

Cold rolled , bright annealed . |

Smooth, shiny and reflective . |

|

|

3# |

Brushed or matte finished on one or both sides . |

No reverse texture, no reflection . |

|

|

4# |

Apply universal polished to one or both sides . |

No directional texture , reflective . |

|

|

6# |

Single side or double side matte satin finish polished , tan leather research mill . |

Matte and no directional texture . |

|

|

7# |

High gloss surface finished . |

Smooth, high reflectance . |

|

|

8# |

8K super mirror finished . |

Directionless texture, high reflectance, clear image . |

|

|

TR |

Cold hardened treatment . |

Should be changed according the material and the cold amount . |

|

|

HL |

Cold rolled, pickled, leveled, grinded . |

Continuous grinding pattern . |

|

|

EN10028-7 Cold Rolled |

2C |

Cold rolled , heat treated , not descaled . |

Smooth with scale from heat treatment . |

|

2E |

Cold rolled , heat treated , mechanically descaled . |

Rough and dull . |

|

|

2D |

Cold rolled , heat treated , pickled . |

Smooth . |

|

|

2B |

Cold rolled , heat treated , pickled , skin passed . |

Smoother than 2D . |

|

|

2R |

Cold rolled , bright annealed . |

Smooth , bright , reflective . |

|

|

EN10028-7 Special Finishes |

1G or 2G |

Ground . One surface only , unless specifically agreed at the time of enquiry and order . |

As standard showing . |

|

1J or 2J |

Brushed or dull polished . |

Smoother than ground . |

|

|

1K or 2K |

Stain Polished . |

As standard showing . |

|

|

1P or 2P |

Bright polished . |

As standard showing . |

|

|

2F |

Cold rolled , heat treated , skin passed on roughened rolls . |

Uniform non-reflective matt surface . |

|

Related products

-

Contact Us

● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month;

● Payment terms L/C, T/T;

● It can pack by container or bulk vessel.

● Standard export seaworthy package, it use steel belt with bundle according product’s size.

● We can make it as your requirement. -

Contact Us

● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month;

● Payment terms L/C, T/T;

● It can pack by container or bulk vessel.

● Standard export seaworthy package, it use steel belt with bundle according product’s size.

● We can make it as your requirement.

Reviews

There are no reviews yet.