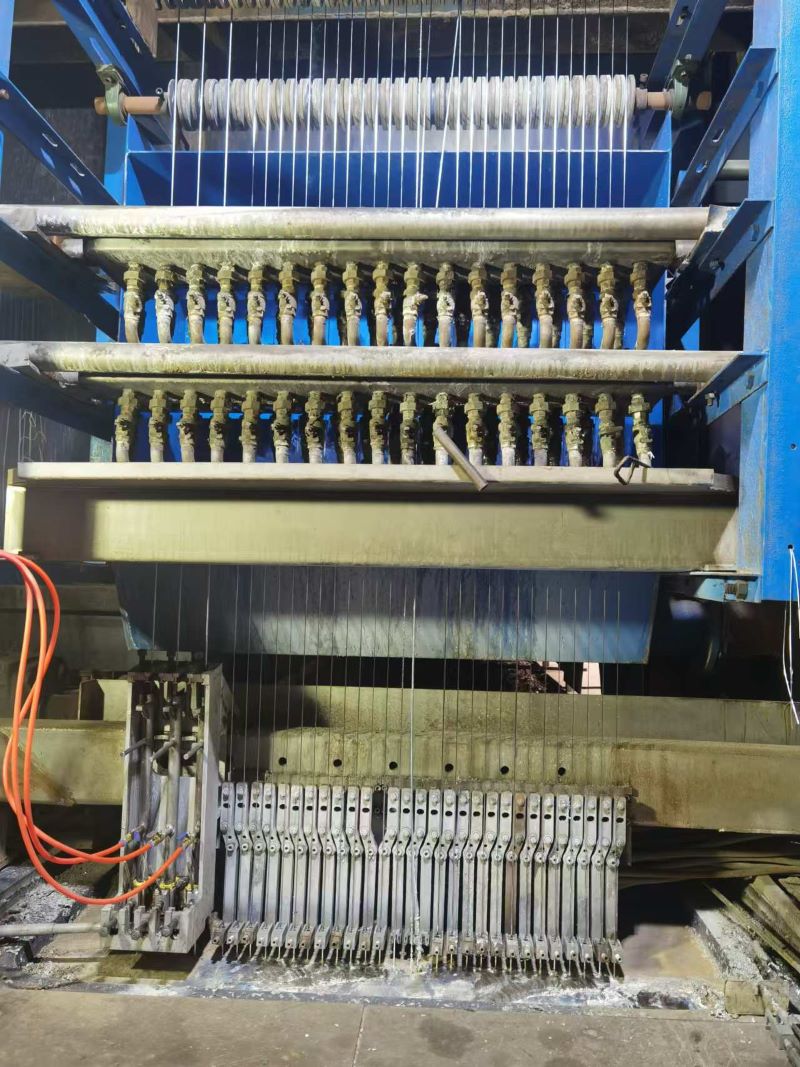

Hot-dip Galvanizing Wire Machine

Products: Low ,medium and high carbon steel wire Diameter range: 0.7~1.6mm, 1.6~4.5mm, 4.5~8.0mm As clients requirement Coat weight range: 40~100 g/m2 ,150~450g/m2

Hot-Dip Galvanizing wire machine

Products: Low carbon steel wire,medium carbon steel wire and high carbon steel wire

Diameter range: 0.7~1.6mm, 1.6~4.5mm, 4.5~8.0mm As clients requirement

Coating Zinc weight range: 40~100g/m2 ,150~450g/m2

Quantity of Wires: 6~100 wires As clients requirement

DV:30~150

Output: 2,000~30,000tons/year

Process flow:

Pay-off passive type for bobbin 1000 →(2)Annealing furnace online→(3)cooling→(4)Smokeless acid washing (HCL)→(5)water flushing →(6)Auxiliary galvanizing→(7)Drying→(8)Hot Dip Galvanizing→(9)Vertical type coiler collecting

Technical Agreement for Heat Treatment Hot Dip Galvanized Wire

Technical requirements for production line

Raw Material: SAE1006

Size wire: φ1.80-4.90mm

Coating Zinc: 45-60g/m2

Tensile strength: 400-500MPa

Product Capacity: 450ton/month

Annealing furnace: working online with natural gas power

Process flow:

(1)Pay-off passive type for bobbin 800 (10m)→(2)Annealing furnace online(22m) →(3)Air cooling(15m) + water cooling(3m)→(4)Smokeless acid washing (HCL)(12.5m)→(5)water flushing 3 stages (3.2m)→(6)Auxiliary galvanizing(2m)→(7)Drying(6m)→(8)Hot Dip Galvanizing(6.5m)→(9)Vertical type coiler collecting(10m)

Design parameters:

Raw material: Low carbon steel wire SAE1006

Size wire: φ1.8-4.9mm

Main size: φ2.70mm

Design DV value: 50m/min

Working speed Max: 28m/min

Product lines: 12 lines in total length 105mm

Furnace Type Online Annealing Furnace Natural Gas

The entire furnace adopts a countercurrent open flame heating furnace type, with separate temperature control and atmosphere adjustment for each section. Adopting hot air and gas heating technology, the main characteristics of this furnace type are the use of open flame heating, under oxygen and over oxygen combustion, and control.

Compared with other furnace types, the full hot air control technology can save gas energy consumption to the greatest extent and reduce production and operating costs

The ignition of each burner, flame detection, temperature control, air and gas ratio coefficient, safety faults, etc. are all fully automatically controlled by the program.

Wiping Galvanizing Wire System

Asbestos block wipe system

Can

be used to produce zinc coated thin steel wire; The wire enters between

the two wipes and the liquid zinc is squeezed and falls back to the

zinc pool

Nitrogen wipe system

The

nitrogen air knife system is designed to have high thickness zinc

layers between a wide line speed. Each wire leaves the zinc-aluminum

liquid and is protected in a ring by its own nitrogen gas knife

N2 wiping:nitrogen

is blown to the surface of the steel wire by an air knife, which can

smooth the zinc layer on the surface of the steel wire. Meanwhile, the

weight of the zinc layer can be adjusted by controlling the nitrogen

pressure

Reviews

There are no reviews yet.