Medical Device CDMO

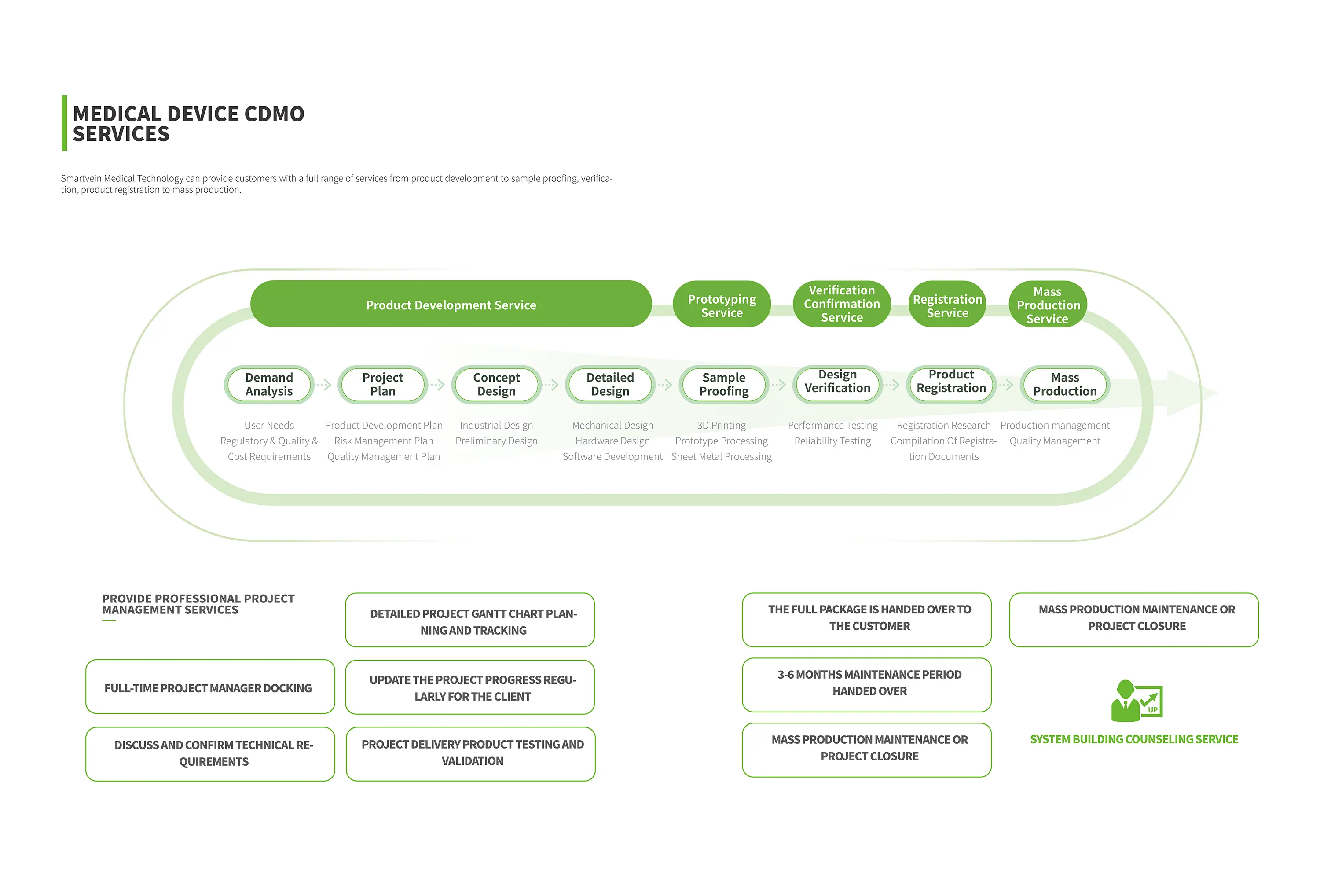

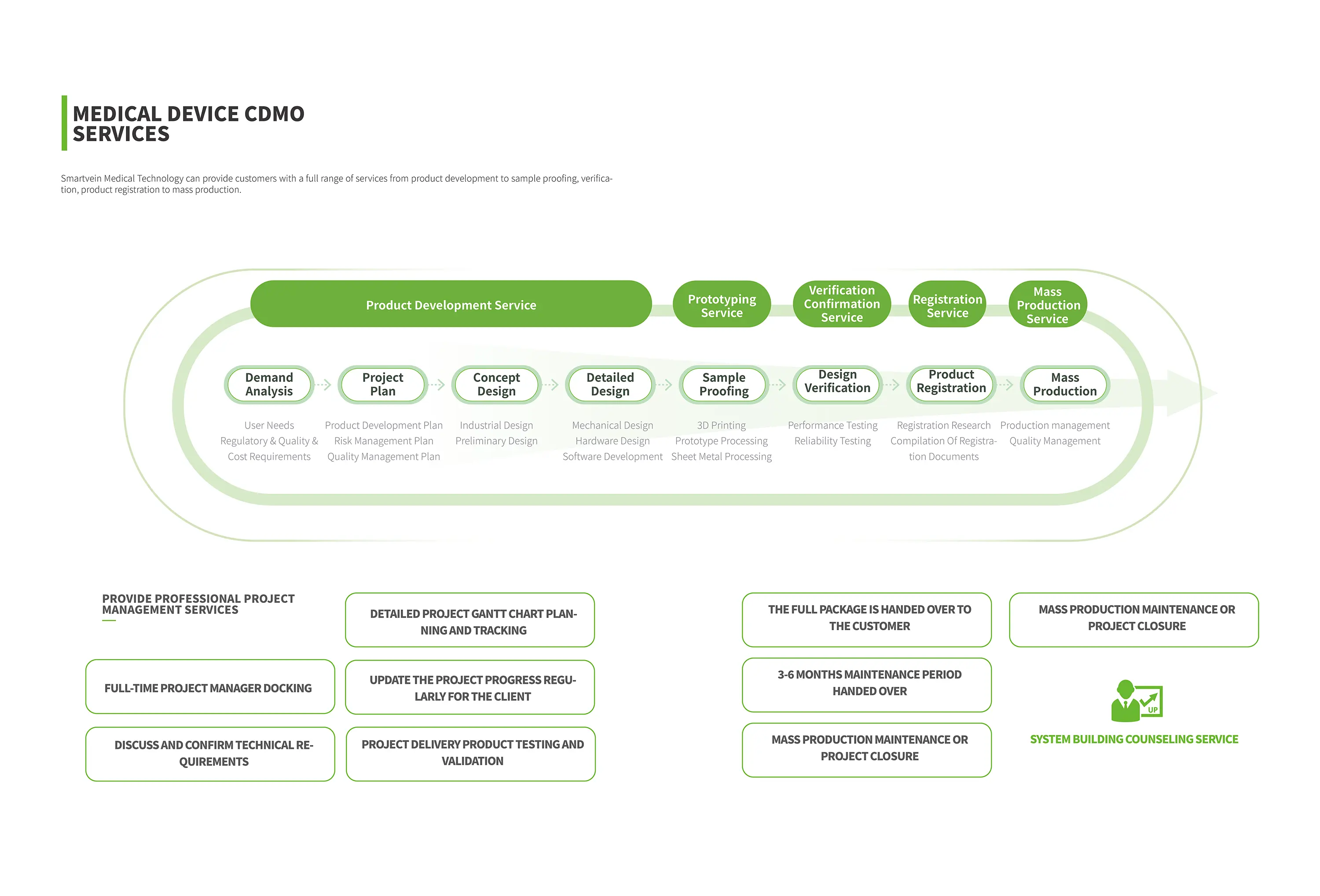

Smartvein Medical Technology can provide customers with a ful ange of services from product development to sample proofing, verifica-tion, product registration to mass production.

In the ever-evolving landscape of healthcare, the demand for cutting-edge medical technology is at an all-time high. As the industry continues to advance, the need for reliable, efficient, and innovative solutions has never been more critical. Enter Smartvein Medical Technology, a pioneering company dedicated to transforming the way medical devices are developed, verified, and brought to market. With a comprehensive suite of services that spans the entire product lifecycle, Smartvein is your trusted partner in navigating the complexities of medical technology.

Product development service

Sample proofing service

Validation service

Registration service

Mass production service

01 Requirement Analysis

User needs, regulatory needs

Quality requirements, cost requirements

02 Project plan

Product development plan

Risk management plan

Quality control plan

03 Conceptual design

lndustrial design

Preliminary design scheme

04 Detailed Design

Structural design

Hardware design

Software design

05 Sample making

3D printing

Hand plate processing

Sheet metal working

06 Design verification

Performance test

Security testing

07 Product registration

Registration research

Registration strategy planning

Registration document writing

08 Mass production

Production management

Quality control

PROVIDE PROFESSIONAL PROJECTMANAGEMENT SERVICES

Detailed project Gantt chart planning and tracking

Full-time project manager docking

Update the project progress regularly for the client

Discuss and confirm technical requirements

Project delivery product testing and validation

System building counseling service

The full package is handed overto the customer

Mass production maintenance or project closure

3-6 months maintenance period handed over

Mass production maintenance or project closure

Medical Device CDMO: A Comprehensive Guide from Concept to Commercialization

1. Definition and Value of Medical Device CDMO

AMedical Device CDMO (Contract Development and Manufacturing Organization) is a third-party service provider specializing in end-to-end development and scalable production for medical device companies. Its core value lies in integrating R&D resources and manufacturing expertise to reduce technical barriers and financial burdens, accelerating product time-to-market. The CDMO model spans the entire lifecycle—fromconcept validation, prototyping, clinical trial support, tofinal production—and is particularly tailored for innovative, complex Class II/III medical devices.

2. Service Principles and Technical Support

CDMOs operate onmodular workflows anddigital collaboration platforms, leveraging cutting-edge technologies for precision manufacturing. Key tools include:

•Computer-Aided Design (CAD) andFinite Element Analysis (FEA) for optimizing device performance.

•3D printing for rapid prototyping and iterative design.

•Automated production lines ensuring batch-to-batch consistency.

Critical processes likebiocompatibility testing, sterilization validation, andquality management systems adhere to global standards such asISO 13485 andFDA 21 CFR Part 820.

3. Typical Applications and Product Types

CDMO services are widely adopted in fields like:

•Orthopedic implants, cardiovascular devices, minimally invasive surgical tools, andintelligent wearables.

Specialized expertise shines in:

• Complex structures (e.g., artificial joints).

• High-precision micro/nano devices (e.g., drug-eluting stents).

• Sterilization-sensitive products (e.g., heart valves).

For startups or teams lacking production capabilities, CDMOs offerend-to-end solutions to bypass costly self-built facilities.

4. Competitive Advantages Over Traditional Contract Manufacturing

CDMOs differentiate through:

1.Technical Depth: Cross-disciplinary teams skilled in materials science, biomechanics, and clinical translation.

2.Flexible Capacity: Agile production lines accommodating small-batch orders and rapid scaling.

3.Regulatory Agility: Proactive adaptation to global regulatory changes (e.g., EU MDR, FDA updates).

Additional strengths includeopen innovation labs for joint R&D, shortening development cycles.

5. Key Design Considerations for CDMO Alignment

Designers must prioritize:

•Regulatory Readiness: EmbedDesign for Manufacturability (DFM) early to align with target markets (e.g., FDA, CE).

•Modular Architecture: Standardized interfaces and modular components for production flexibility.

•Material Selection: Prioritize stable, biocompatible materials (e.g., PEEK, titanium alloys) while balancing cost-effectiveness. CDMOs often provideDFMEA tools to mitigate risks.

6. Material Innovation Trends in High-End Medical Devices

Current trends emphasizehigh-performance biomaterials:

•Orthopedics: Porous tantalum, ceramic composites for enhanced bone integration.

•Cardiovascular: Biodegradable polymer scaffolds replacing traditional metals.

•Wearables: Flexible circuits and liquid metals for next-gen smart devices.

CDMOs maintain proprietary material libraries and collaborate with research institutions for patented formulations.

7. Selecting a One-Stop CDMO Partner: Key Criteria

Evaluate providers based on six dimensions:

1.Technical Completeness: Full-service capabilities from design to certification.

2.Production Scalability: Cleanroom capacity, equipment redundancy, and rapid response times.

3.Intellectual Property Protection: Robust data encryption and NDA enforcement.

4.Global Regulatory Expertise: Track record of successful CE/FDA approvals.

5.Cost Transparency: Detailed pricing models with no hidden fees.

6.Risk Mitigation: Supply chain redundancies and contingency plans. Recommend audits and pilot projects for validation.

8. Innovative CDMO Solutions Addressing Industry Pain Points

Leading CDMOs offer tailored solutions:

•Expedited Pathways: Combined biocompatibility testing and parallel regulatory submissions, slashing time-to-market by 40%.

•Flexible Manufacturing: Hybrid approaches (3D printing + CNC machining) lowering minimum order quantities.

•Digital Twin Technology: Virtual validation systems reducing physical prototypes. For example, a ventilator component project cut design cycles by 60% and defects to0.12 ppm.

Reviews

There are no reviews yet.