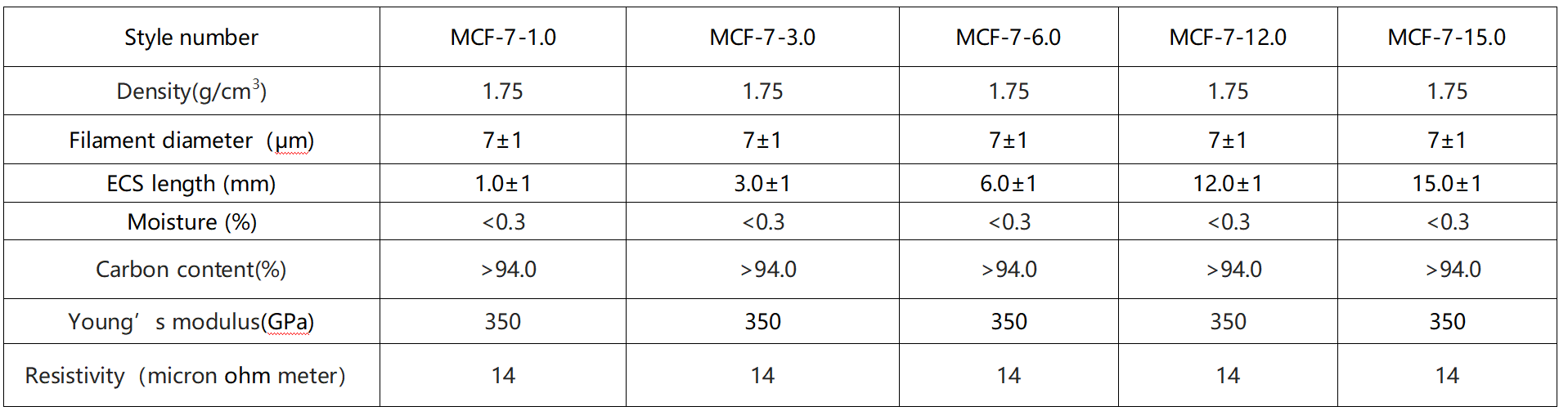

T700 chopped short carbon fiber

Chopped carbon fiber is a fibrous material made by cutting continuous carbon fiber tows into specific lengths.

T700 chopped short carbon fiber-Carbon fiber chopped strands are obtained by cutting PAN carbon fiber precursor filaments into specific lengths using cutting machines. Due to carbon fiber's superior properties such as high strength, high modulus, low density, high electrical conductivity, low thermal expansion coefficient, low friction coefficient, acid and alkali resistance, and good stability under most environmental conditions and chemical reagents, it has been used as a reinforcing material for various thermosetting and thermoplastic resins. Adding a certain amount of carbon fiber chopped strands to resins can significantly improve various properties of products, such as enhancing the strength and modulus, increasing the hardness, improving dimensional stability and crack resistance, and boosting wear resistance of the products.

Reviews

There are no reviews yet.