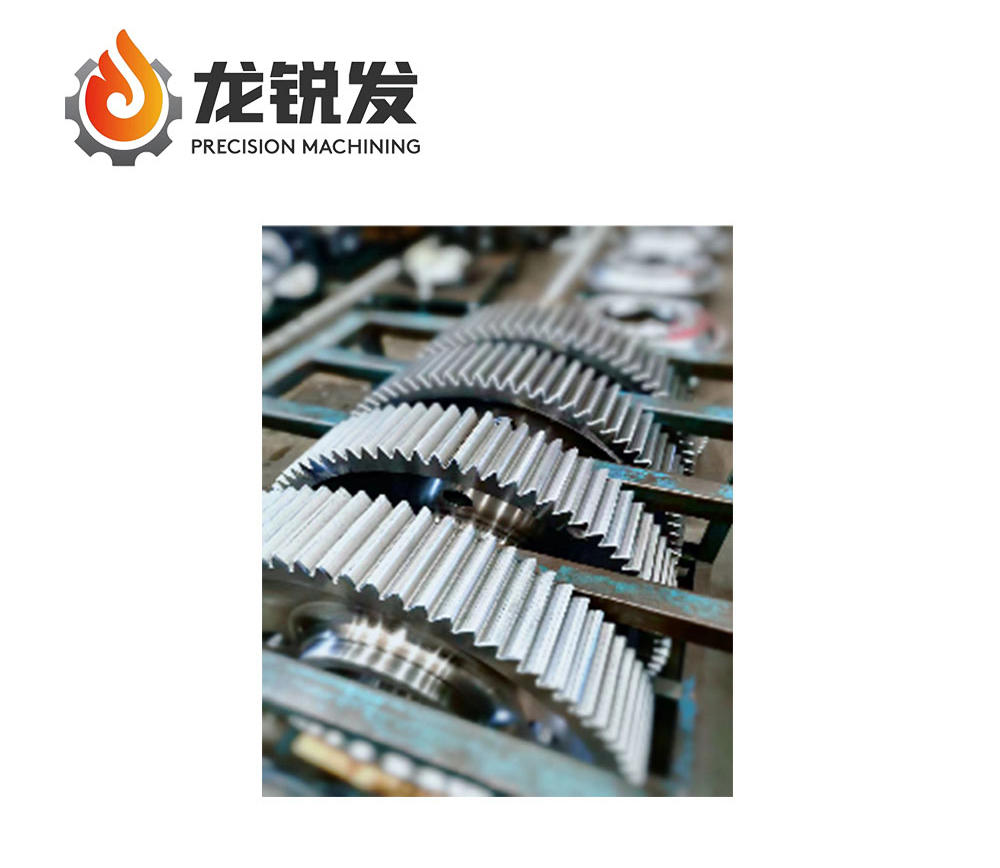

Rail transportation gears

Rail transportation gears are core components of the transmission systems in railway locomotives and rolling stock.

Core Structural Features

1. Transmission Structure Design

Locomotive drive gears commonly use a combination of helical gears and spiral bevel gears. Helical gears provide smooth transmission with high contact ratio, reducing noise at high speeds (operating noise ≤ 85 dB). Spiral bevel gears accommodate the spatial angle requirements of locomotive power transfer, with single-stage transmission ratios ranging from 1:8 to 1:15.

High-speed train (EMUs) gearboxes adopt a lightweight layout combining planetary gears and parallel-shaft gears. The planetary gear system distributes load, reducing stress on individual teeth, and decreases overall gearbox weight by approximately 20% compared to traditional designs, meeting the high-speed, lightweight requirements of EMUs.

2. Materials and Manufacturing

Gear blanks are made of high-strength alloy carburizing steels such as 20CrNi2Mo and 17CrNiMo6. Through carburizing, quenching, and gear grinding, tooth surface hardness reaches HRC 58–62, core hardness HRC 30–40, significantly enhancing fatigue strength and wear resistance, with a design life exceeding 3 million kilometers.

Gear accuracy meets GB/T 10095 Grade 5 or higher, with tooth surface roughness Ra ≤ 0.8 μm, ensuring precise and smooth transmission.

3. Sealing and Protective Structure

A dual sealing design combining labyrinth seals and lip oil seals protects against dust, rain, and ice/snow during railway operation, achieving IP65 protection rating.

Gearboxes incorporate a forced lubrication and cooling system, circulating oil to remove heat generated by transmission, maintaining oil temperature between 20–80 °C, suitable for extreme environments from -40 °C to 60 °C.

Main Functions and Applications

1. Traction Power Transmission

Converts the locomotive traction motor’s high-speed, low-torque output (~3000 r/min) into low-speed, high-torque output for wheelsets (~300 r/min), enabling train traction, with transmission efficiency ≥ 98% to ensure efficient power delivery.

EMU gearboxes provide precise speed matching so the traction motor output aligns with wheelset speeds, supporting high-speed operation from 200 to 350 km/h.

2. Braking and Speed Regulation Assistance

Works with the train braking system to transmit braking torque in reverse through gears, assisting deceleration and stopping, improving brake response.

In metro and urban rail vehicles, multi-stage gear ratios allow speed adjustment for different operational phases such as start-up, acceleration, and cruising.

3. Operational Stability Assurance

High-precision meshing and load-sharing design absorb track-induced impact loads, reducing wheelset and bogie vibrations, enhancing ride smoothness and comfort.

Fatigue-resistant structure ensures long-term reliable operation under cyclic loads, meeting railway transport standards of “zero-failure, high reliability.”

Product selling points & advantages

Good hardenability and machinability

High surface hardness

Tooth modifcation

Good gear mesh performance,low meshing impact,low meshing noise

High load capacity

Tooth width load equally distributed

High resistance to wear

High precision grade

Stability in drivingHigh accuracy of meshing movement

Long operating life

High transmission effciency

Constant transmission ratio

Small vibration

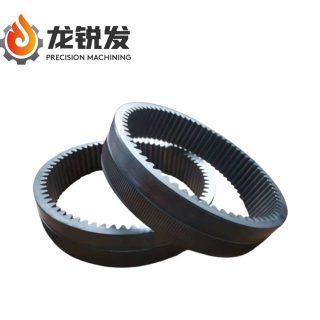

The company's main products are high-precision involute gears and gear shafts. We specialize in the manufacturing of spur gears, helical gears, herringbone gears, external splines, internal splines, cycloidal wheels, pin gear shells, new energy automobile gears and other gear products .

Products are widely used in the wind power industry: wind turbine planetary gears, sun gears, high-speed gears, ring gears, etc., rail locomotive industry, shipbuilding industry, petroleum industry, aviation gears, compressor gears, RV reducer cycloid wheels and pin gear shells, Coal mining machinery and reducer industry, lifting machinery and many other industries.

Our customers include CRRC, Yuanjing, Italian Cappi Gear, Double Ring Transmission, Guomao Reducer, NGC, Hitachi Compressor, etc.

The types of material are: forge piece, dieforge piece,castings,welded piece,steel rods and so on. The various heat treatment methods applied todifferent raw materials are : carburizing and quenching, sub-zero treatment ,gas nitriding,ionitriding,induction quenching, overallquenching,hardening and tempering and so on.

For heavy duty and high speed gears, materials containing Ni such as 17CrNiMo6.18CrNiM07-6.18Cr2Ni4WA are adopted. This type of materialhas high core toughness and surface hardenss with strong bending resistance and torque resistance after approperiate carburizing and quenching.High hardness surafce and high accuracy grinding makes the tooth surface become highly wear resistant.

We can process gear of precison grade as per diferent national standards: such as DlN 3-6 grade,AGMA10-13 grade,1s0 3-6 grade, jls 0-2 grade GB 3~6 grtade , etc.

We can also make modifcations to various tooth profles and helixes according to the diferent applications as wellas customer's requirements . Themain modifcation methods aplied to gear grinding machine with form wheel are: crowned shape ,crowned shape with slope,K shape, tooth widthasymmetric modifcation. Tooth surface roughness may reach Ra0,4. Appropriate modiication and relatively high tooth surface roughness mayeffectively control the meshing noise and prolong the service life.

Reviews

There are no reviews yet.